How Workplace Exposure Monitoring Protects Your Workers and Business

Workplace exposure monitoring gives property managers, building managers, facility managers, and office managers the early warning system they need to protect their people. By systematically tracking air quality, noise levels, and potential chemical exposures, you can identify problems before they become expensive emergencies or regulatory violations.

Your workplace exposure monitoring program should include:

- Air sampling – captures vapors, dust and fumes in breathing zones

- Noise monitoring – identifies sound levels that endanger hearing

- Biological monitoring – verifies whether chemicals are entering the body

- Physical-hazard checks – heat, vibration, radiation and similar stresses

- Standards comparison – OSHA, ACGIH and NIOSH limits guide actions

- Recordkeeping – results stored for 30 years for compliance and claims defense

An estimated 18,000 new work-related respiratory cases each year stem from uncontrolled exposures, according to agencies like the National Institutes for Health (NIH). That means potential lawsuits, insurance premium increases, employee and tenant complaints, and the operational nightmare of emergency remediation during peak occupancy periods.

The regulatory landscape is tightening too. OSHA now requires exposure records to be accessible within 15 working days, and states like California are dramatically lowering permissible exposure limits—meaning yesterday’s “safe” levels could trigger tomorrow’s violations.

The good news? Technology is making proactive monitoring more accessible than ever. Video exposure monitoring can link real-time readings to specific maintenance tasks or tenant activities, while direct-read sensors provide instant alerts when thresholds are exceeded.

Workplace Exposure Monitoring

Picture this: Your facility is humming along perfectly—tenants are satisfied, maintenance crews are productive, and everything looks spotless. But beneath this smooth operation, an invisible drama is unfolding. Chemical vapors from cleaning products are accumulating in poorly ventilated areas. HVAC systems are circulating microscopic particles. That “routine” construction project on the third floor is generating dust that’s drifting throughout the building. Meanwhile, your maintenance team is exposed to noise levels that could permanently damage their hearing.

This is your facility’s hidden ecosystem—and without proper monitoring, you’re flying blind through a minefield of potential health hazards, liability risks, and non-compliance with regulatory standards.

Exposure monitoring transforms these invisible threats into actionable intelligence. Instead of waiting for someone to get sick or for an inspector to show up with a citation, you get real-time data that lets you intervene before problems escalate.

Your regulatory roadmap has three key landmarks:

- OSHA Permissible Exposure Limits (PELs) – The legal floor you absolutely cannot cross

- ACGIH Threshold Limit Values (TLVs) – Science-based standards that are often more stringent (and more current) than OSHA requirements

- NIOSH Recommended Exposure Limits (RELs) – The gold standard based on the latest research

Here’s the smart manager’s strategy: When these standards conflict, always choose the most protective limit. It’s far cheaper to prevent exposure than to deal with the legal, financial, and operational fallout of a workplace illness or regulatory violation.

What Is Workplace Exposure Monitoring?

At its core, monitoring is part of the industrial-hygiene cycle—Anticipate, Recognize, Evaluate, Control, and Confirm (ARECC). Data from properly calibrated instruments tell you whether engineering controls work and whether personal protective equipment (PPE) is truly the last line of defense.

Common Hazards That Require Exposure Monitoring

- Silica dust from cutting concrete or stone can cause silicosis and lung cancer.

- Asbestos fibers are still found during renovation and other construction activities and must be contained.

- Welding fumes mix metals and gases that spike during specific welds.

- Solvents in cleaning and painting pose acute and chronic health risks.

- Heat stress, EMF, noise and vibration also warrant periodic checks.

For a closer look at crystalline silica risks, see Respirable Crystalline Silica: The Health Risks of Exposure.

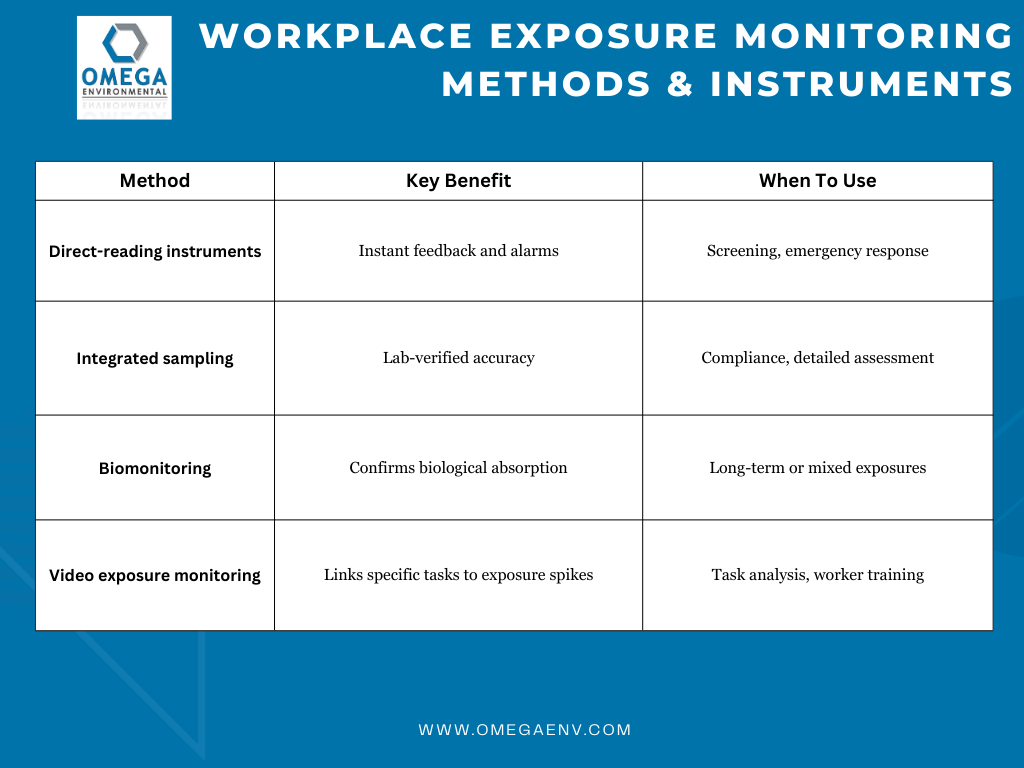

Core Methods and Instruments

Calibration is critical; an uncalibrated sensor is little better than guesswork.

Building an Exposure Monitoring Program

A monitoring plan should feel less like paperwork and more like a safety net—catching problems before they reach your people.

- Group similar exposure groups (SEGs). Sampling one representative welder is more meaningful than random spot checks.

- Compare to the most protective OEL. Eight-hour time-weighted averages (TWAs) and 15-minute short-term exposure limits (STELs) both matter; spikes can be as damaging as all-day exposures.

- Turn numbers into action. Analytics highlight trends—such as rising dust when filters clog—so maintenance or ventilation upgrades happen before OSHA citations do.

- Retain records for 30 years. Chronic illnesses often develop slowly; documentation protects both workers and your organization.

Acting on Results of Workplace Exposure Monitoring

If monitoring shows an over-exposure:

- Eliminate the task if possible.

- Substitute safer materials.

- Engineer controls—local exhaust, isolation or automation.

- Administrate—rotate staff or shorten tasks.

- Equip workers with PPE as a final barrier.

Regular audits keep the program current, while medical surveillance spots health effects early.

Visit our website to learn more about Occupational Health Services like medical surveillance.

Roles, Training and Follow-Up

- Employers develop written plans, provide results within 15 days and maintain records.

- Employees participate in sampling and can request additional monitoring.

- Regulators verify that plans exist, and controls are effective.

See What Every Business Needs to Know About Workplace Exposure Monitoring for supplemental guidance.

Why Bother With Workplace Exposure Monitoring?

Workplace exposure monitoring is the systematic process of measuring and evaluating worker exposure to hazardous substances and conditions in the workplace. This critical safety practice involves identifying potential health risks, collecting data on exposure levels, and implementing controls to protect workers from harmful agents.

Key aspects of workplace exposure monitoring include:

- Purpose: Measure risk levels of hazards to keep them within safe limits

- Scope: Chemical, physical, and biological agents in the workplace

- Methods: Air sampling, direct-reading instruments, and laboratory analysis

- Frequency: Regular monitoring based on workplace conditions and regulatory requirements

- Goal: Prevent occupational illness and maintain regulatory compliance

The primary purpose of workplace exposure monitoring goes beyond simple compliance – it serves as both a legal requirement and a strategic business investment. When exposure limits are exceeded, work must cease until risks are reduced or additional controls are implemented. This proactive approach protects workers from acute and chronic health problems while helping businesses avoid costly penalties, reduce insurance claims, and maintain productive operations.

Modern workplace exposure monitoring uses sophisticated equipment and methodologies to assess everything from airborne particles to noise levels. Certified Industrial Hygienists typically conduct this specialized work, using personal sampling devices, area monitors, and direct-reading instruments to gather accurate data. The results inform critical decisions about engineering controls, administrative procedures, and personal protective equipment.

The Core Components of Workplace Exposure Monitoring

This section breaks down the critical aspects of a successful monitoring program, from understanding its importance and identifying hazards to implementing correct methodologies and interpreting the results for ongoing safety and compliance.

The Human Cost: Why Safety Must Come First

Let’s start with the human element: worker safety. Your employees are your most valuable asset, and their health is top priority. The statistics paint a sobering picture that no one can ignore:

- 19,000 new cases of work-related breathing or lung problems occur each year in the U.S. (OSHA)

- 50,000 deaths annually in the U.S. are related to past chemical exposures (OSHA)

Workplace exposure monitoring serves as an early warning system, identifying and quantifying risks before they lead to such devastating outcomes.

The Business Case for Workplace Exposure Monitoring: Smart Strategy, Real Returns

Compelling business benefits make monitoring a smart financial decision. Think of it as insurance for your operations—the kind that actually prevents problems rather than just paying for them after they happen.

Legal Compliance and Risk Management

Legal compliance forms the backbone of any monitoring program. Regulations like OSHA’s Permissible Exposure Limits (PELs) place clear responsibilities on employers to control exposure to hazardous substances. Non-compliance isn’t just a slap on the wrist—it can result in substantial fines, legal action, and reputation damage that can take years to repair.

Workplace exposure monitoring provides the documented evidence you need to demonstrate adherence to these critical standards.

Key compliance benefits include:

- OSHA compliance protects you from substantial fines and legal action

- Documented evidence proves adherence to critical safety standards

- Reputation protection prevents years of damage from non-compliance issues

Financial Benefits

The financial benefits extend far beyond avoiding penalties. Reduced liability and lower insurance costs naturally follow when you proactively identify and mitigate hazards. By staying ahead of potential problems, you significantly reduce your exposure to workers’ compensation claims and costly litigation. Insurance companies recognize and reward businesses with robust safety programs, often translating to lower premiums that can save thousands annually.

Specific financial advantages:

- Reduced liability from proactive hazard identification and mitigation

- Lower insurance costs through robust safety programs (insurers often reward proactive businesses with reduced premiums)

- Fewer workers’ compensation claims and costly litigation

Operational Advantages

Perhaps most importantly, improved productivity and employee morale create a positive feedback loop that benefits everyone. When workers feel their health is genuinely prioritized, trust and confidence flourish. This leads to increased productivity, reduced absenteeism, and higher retention rates. A healthy workforce is simply a more productive workforce—it’s that straightforward.

These operational benefits include:

- Improved productivity when workers feel their health is prioritized

- Higher employee morale creates trust and confidence

- Reduced absenteeism and better retention rates

- Enhanced workplace culture through demonstrated commitment to safety

Staying Ahead of Change

Responding to complaints and preventing future issues becomes much more manageable with a solid monitoring program in place. Exposure monitoring can be triggered by employee complaints about health symptoms, concerns about new processes, or changes in workplace conditions. Addressing these issues swiftly and scientifically demonstrates your commitment to safety and helps prevent minor concerns from escalating into major problems.

A solid monitoring program helps you adapt to evolving workplace conditions:

- Employee complaints about health symptoms or workplace concerns

- New processes and equipment installations

- Process changes and emerging hazards

- Government contract compliance requirements

The program also helps you understand risks from new conditions, maintain government contract compliance, and adapt to changing workplace environments. Whether you’re dealing with process changes, new equipment installation, or emerging hazards, monitoring provides the data-driven insights you need to make informed decisions.

At Omega Environmental Services, we’ve seen how prioritizing worker health and safety creates strategic business advantages. Our comprehensive approach goes beyond simple compliance to build safer, more resilient operations. For a deeper understanding of how comprehensive assessments work, explore The Complete Guide to Industrial Hygiene Assessments. We also offer specialized guidance to help you Prevent Chemical and Legal Exposure with a Chemical Exposure Risk Assessment.

Identifying Workplace Hazards: What to Assess

Before you can monitor effectively, you need to know what you’re looking for. Workplace exposure monitoring requires a comprehensive understanding of the various hazards that could impact worker health. This identification process is the crucial first step in any effective industrial hygiene program.

Workplace hazards fall into several distinct categories, each requiring different monitoring approaches and control strategies. Understanding these categories helps you develop a more targeted and effective monitoring program.

Chemical Agents

Chemical agents represent the most common category of workplace hazards. These substances can cause harm through inhalation, skin contact, or ingestion. They might be materials used directly in work activities like paint, cleaning chemicals, or disinfectants. They could also be produced during work activities, such as dust or fumes from welding, or occur naturally like grain dust in agricultural settings.

Gases like carbon monoxide, hydrogen sulfide, nitrogen dioxide, and sulfur dioxide are often colorless and odorless, making monitoring absolutely essential for worker safety.

Vapors from evaporated liquids including solvents like toluene and benzene, paints, and adhesives can accumulate in poorly ventilated areas. Fumes consist of fine solid particles formed from vapor condensation, often generated by processes like welding or metal pouring.

Dusts deserve special attention because they’re so common across industries. Wood dust, silica dust from concrete and stone work, asbestos in older buildings, and general particulate matter all pose significant health risks. Respirable crystalline silica, for instance, poses particularly serious health risks that every facility manager should understand. Learn more about Respirable Crystalline Silica: Health Risks of Exposure.

Mists from spray painting or cleaning operations and various industrial chemicals including acids, bases, and pesticides round out the chemical hazard category. Each requires specific monitoring approaches and control measures.

Physical Agents

Physical agents represent non-chemical forms of energy that can cause harm. Noise exposure can lead to hearing loss, stress, and reduced concentration. OSHA requires periodic testing for workers in noisy environments, making this a critical compliance issue. Vibration, both hand-arm and whole-body, can cause musculoskeletal disorders, particularly in construction and manufacturing settings.

Temperature extremes present risks ranging from heat stress and heatstroke to hypothermia and frostbite. Radiation includes both ionizing radiation like X-rays and gamma rays, and non-ionizing radiation from electromagnetic fields, UV light, and microwaves. Even lighting conditions, whether insufficient or excessive, can cause eye strain and increase accident risk.

Biological Agents

Biological agents include living organisms that can cause disease or allergic reactions. Bacteria and viruses became a heightened concern during the COVID-19 pandemic, but they’ve always been workplace hazards in healthcare, food service, and other industries. Mold and fungi are common indoor air quality problems that can cause respiratory issues and allergies. Our expertise in Clearing the Air on Indoor Air Quality Testing helps identify and address these biological hazards.

Allergens like pollen, animal dander, or certain plant materials can trigger reactions in sensitive workers, affecting productivity and comfort.

Common hazardous materials that require regular assessment include asbestos in building materials during renovation or demolition projects. Protecting Workers from Asbestos Exposure is a critical concern for any facility manager dealing with older buildings. Lead in old paint, welding operations, or battery manufacturing poses both acute and chronic health risks.

Volatile Organic Compounds (VOCs) from paints, solvents, and cleaning products can accumulate in indoor environments. Diesel exhaust particulates affect workers in transportation, construction, and industrial settings. Welding fumes contain various toxic metals and require specialized monitoring approaches.

The key to effective hazard identification lies in understanding your specific workplace processes, materials used, and potential exposure pathways. This comprehensive approach forms the foundation for targeted monitoring and effective control measures. For buildings and facilities, conducting thorough assessments helps identify hidden hazards that might otherwise go unnoticed. Learn more about How to Conduct a Hazardous Materials Assessment in Buildings.

Developing a Proactive Exposure Control Strategy

For property managers, facility managers, and risk managers, developing a comprehensive exposure control strategy represents a fundamental shift from reactive firefighting to proactive management that drives long-term success.

Think of it this way: would you rather fix a leaky roof after water damage has already occurred, or identify and address potential problems before they become costly disasters? The same principle applies to workplace exposure monitoring. A truly proactive strategy moves beyond simply reacting to incidents, complaints, or regulatory inspections. Instead, it creates a systematic approach to continuous improvement that anticipates problems before they develop.

This proactive approach is informally known as ARECC, and it involves implementing the continuous cycle we discussed earlier – anticipating hazards, recognizing exposure sources, evaluating risk levels, implementing effective controls, and confirming protection. But what does this look like in practice?

Breaking Down ARECC

Anticipate

Anticipating hazards means understanding the potential health risks associated with new processes, materials, or technologies before they’re introduced into your workplace. When you’re planning a renovation project, expanding operations, or bringing in new equipment, proactive exposure monitoring helps you identify potential risks early. This foresight allows for preventative measures rather than reactive scrambling after problems surface.

Recognize

Recognizing exposure sources involves systematically identifying all potential sources of hazardous agents and conditions within your facilities. This includes routine daily tasks, non-routine maintenance activities, and even emergency scenarios. It’s about developing a comprehensive understanding of your workplace from a safety perspective, not just an operational one.

Evaluate

Evaluating risk levels requires accurately measuring and assessing worker exposure using appropriate methodologies and qualified professionals. This means comparing results against established limits and understanding what these findings mean for your specific situation. It’s not enough to simply collect data – you need to understand what it’s telling you about your workplace safety.

Control

Implementing effective controls involves applying the Hierarchy of Controls we discussed earlier, prioritizing elimination and engineering solutions to mitigate hazards at their source. This reduces reliance on less effective administrative controls and personal protective equipment. The goal is to design safety into your processes rather than trying to protect against unsafe conditions.

Confirm

Confirming protection means regularly monitoring to verify that control measures remain effective, exposure levels stay controlled, and worker health is protected. This continuous feedback loop drives ongoing improvement and adaptation as conditions change.

The benefits of this approach extend far beyond simple compliance. Risk mitigation through proactive monitoring reduces the likelihood of costly health incidents and associated workers’ compensation claims. It minimizes regulatory fines and legal liabilities while improving worker morale and productivity. When employees see that their health and safety are genuine priorities, they’re more engaged, productive, and loyal.

This approach also safeguards your organization’s reputation. In an era where corporate responsibility matters more than ever, demonstrating a commitment to worker safety can differentiate your organization in the marketplace. It transforms hazard control from a burden into a strategic investment that underpins the health of your business.

By partnering with qualified experts, facility and risk managers can move beyond simple compliance to create a truly safe, healthy, and productive work environment. A robust exposure monitoring program is a cornerstone of modern occupational health and a critical investment in your people and your business’s future. For comprehensive support in developing and implementing your strategy, explore our Industrial Hygiene Services.